Can a blown transformer cause a house fire?

Power transformers are essential components of electrical distribution systems, responsible for safely stepping voltages up or down to ensure efficient power delivery. While generally reliable,

We develops and manufactures three major product series and their accessories: outdoor high-voltage sulfur hexafluoride (SF6) circuit breakers rated at 35kV and above, gas-insulated switchgear (GIS), and hybrid gas-insulated switchgear (HGIS).

Taishan high-voltage switches are compact products that require minimal space, leading the industry in safe breaking capabilities, reduced maintenance workload, and grid-friendly features. The products can be customized to include single-line isolators per user requirements, allowing for future expansion without power outages. To align with the national goal of reducing greenhouse gas emissions, mixed gas insulation is available, reducing SF6 usage by 70%. The 252kV GIS rapid grounding switch has passed high-voltage closing tests on the first attempt, placing it among the leaders in the domestic market. The products enable one-click centralized control and confirmation of intelligent substation isolators, with all operating mechanisms achieving a mechanical lifespan of 10,000 cycles, ensuring safety and reliability. The annual gas leakage rate is less than 0.1%, requiring only routine inspections and minimal maintenance. High-voltage testing achieves partial discharge levels below 3 picocoulombs (pc), ensuring equipment operational safety.

Trusted by world-class brands & organizations of all sizes

Taishan Transformer is a key national-level manufacturer specializing in transformers, recognized as a “Contract-Honoring and Promise-Keeping” enterprise, a high-tech enterprise, and a national-level enterprise technology center. It is recommended in the national directory for rural and urban power grid construction and renovation, as well as a recommended supplier of major electromechanical equipment for hydropower projects. Its products have been awarded the title of “National Quality Inspection Qualified Product – Quality Trustworthy Product” and “Nationally Recognized Product for Mechanical Industry Users.

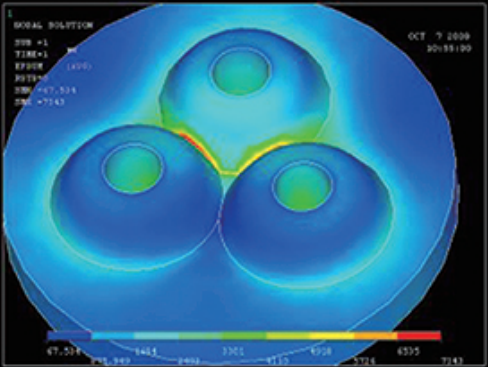

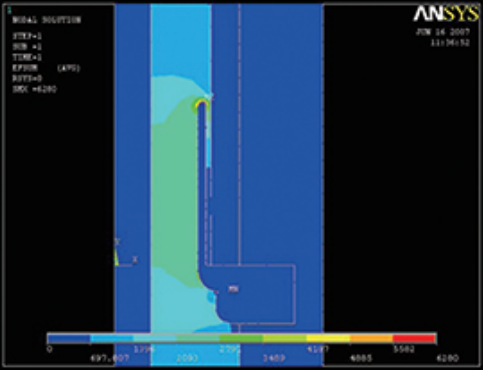

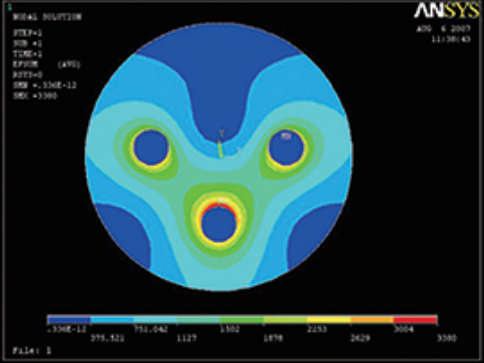

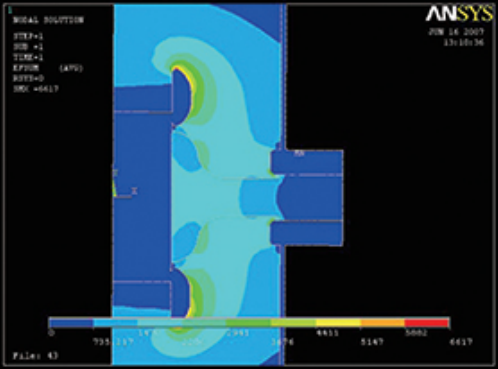

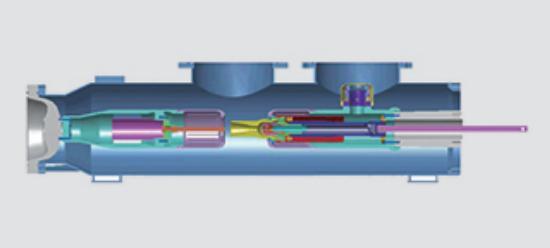

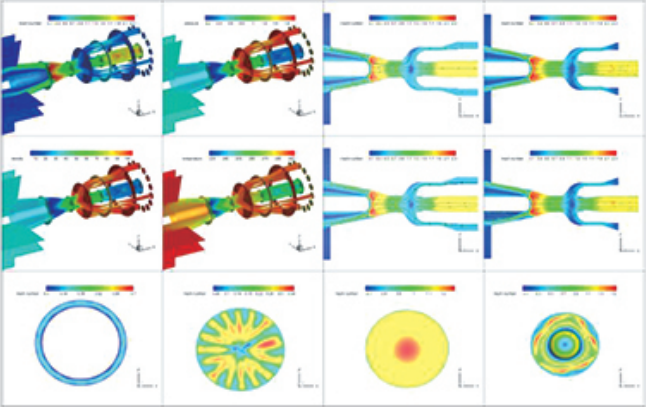

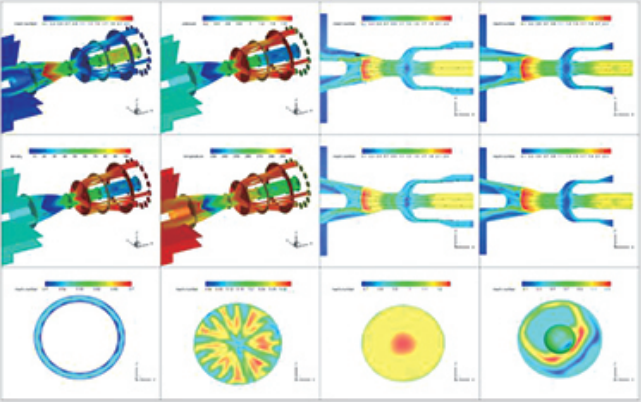

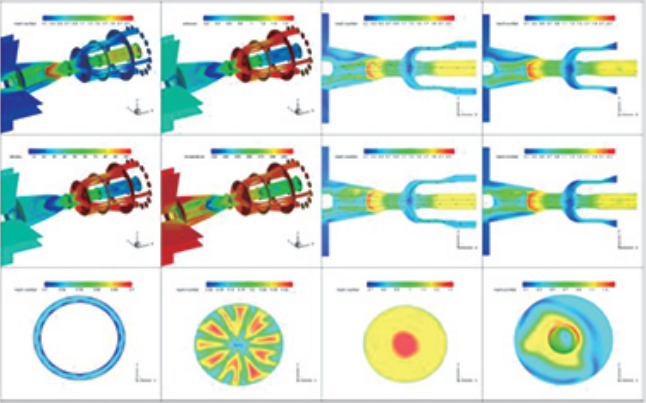

During the product research and development phase, the company concentrated its technical expertise and, based on the digestion and absorption of the world’s most advanced breaking technologies, fully utilized 3D design and analysis software to conduct electric field analysis, breaking performance analysis, airflow analysis, and mechanical strength analysis.

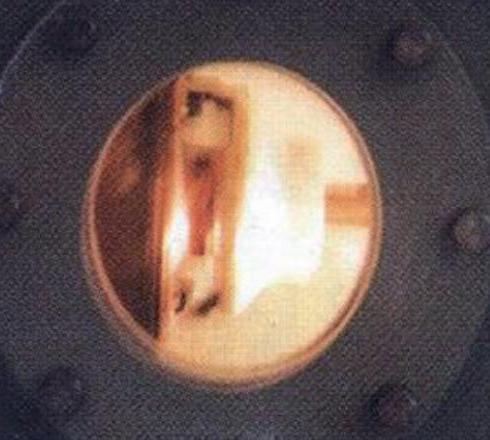

The successful adoption of the self-blast arc-extinguishing principle has endowed the circuit breaker with outstanding advantages, including strong breaking capability, short arcing time, and extended electrical lifespan.

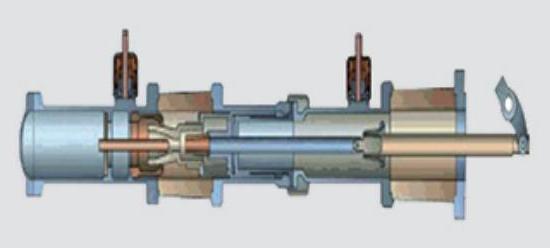

The circuit breaker adopts a self-blast arc-extinguishing chamber based on a new arc-extinguishing principle, featuring a hybrid structure combining self-blast thermal expansion and an auxiliary puffer mechanism. This design fully utilizes the energy of the arc itself, enhancing arc-extinguishing capability and significantly reducing the operational power requirements of the mechanism. Compared to conventional puffer-type arc-extinguishing chambers, it offers stronger breaking performance, shorter arcing time, and a full breaking time of just 3 cycles. It also boasts extended electrical lifespan, with a full-capacity breaking ability of up to 22 times.

The structure is simple yet highly reliable. The self-blast arc-extinguishing principle ensures dependable breaking performance for rated short-circuit currents as well as any fault currents, providing ample arcing time margin. Inheriting the structural features of puffer-type circuit breakers, it minimizes the number of components in the arc-extinguishing chamber, enhancing the electrical reliability of the product.

The Taishan high-voltage switches demonstrate advanced technology and innovation in high-voltage electrical equipment. These features make Taishan high-voltage switches ideal for applications where safety, efficiency, and environmental sustainability are priorities. Key features and advantages of these products include:

- Space Efficiency: Compact products requiring minimal space.

- Customizability: Options to include single-line isolators tailored to user needs, enabling future expansion without power interruptions.

- Reduced SF6 Usage: Mixed gas insulation technology reduces SF6 usage by 70%, supporting national goals to cut greenhouse gas emissions.

- Safe Breaking Capabilities: Industry-leading breaking safety standards.

- Low Gas Leakage: Annual gas leakage rate under 0.1%, minimizing maintenance needs.

- Mechanical Durability: Operating mechanisms with a mechanical lifespan of 10,000 cycles.

- Partial Discharge Control: High-voltage testing achieving partial discharge levels below 3 picocoulombs, ensuring operational safety.

- Intelligent Control: One-click centralized control and confirmation for substation isolators. - Grid-Friendly Operations: Features aligned to reduce maintenance workload and integrate smoothly with grid operations.

The 252kV GIS rapid grounding switch passed high-voltage closing tests on the first attempt, solidifying its position as a domestic leader in performance.

When purchasing an Gas Insulated Switchgear (GIS), you may want to know the following questions & answers.

The rated voltage and current capacity of Gas Insulated Switchgear (GIS) depend on the specific design, manufacturer, and application for which the GIS is intended. However, I can provide you with a general overview of typical specifications for GIS systems in common industrial and utility applications.

GIS systems are designed for high-voltage applications, typically ranging from:

Medium Voltage GIS:

High Voltage GIS:

Ultra High Voltage GIS:

The rated current capacity of a GIS is primarily dependent on the system’s design and its intended application. Some general values are:

However, GIS systems can be designed for even higher currents depending on the requirements. For example:

These values can vary based on the design and application. Would you like to know about specific GIS models or manufacturers for more detailed specifications?

The design life expectancy of Gas Insulated Switchgear (GIS) is typically in the range of 30 to 40 years. This is a general benchmark, but the actual lifespan can vary depending on several factors, such as:

While the typical design life expectancy of GIS is 30 to 40 years, the actual life span can be influenced by factors like maintenance, operational stress, environmental conditions, and technological upgrades. Proper monitoring and care can ensure that a GIS remains functional and safe beyond its initial design life.

Yes, Gas Insulated Switchgear (GIS) can be highly customized to meet specific operational requirements, and this is one of its key advantages. GIS is designed to be flexible and adaptable, offering various configurations, ratings, and features to suit different environments, applications, and operational needs. Here’s how GIS can be customized:

In summary, GIS systems are highly customizable to meet a wide range of operational, environmental, and regulatory needs. From voltage and current ratings to advanced protection, automation, and gas handling systems, GIS can be specifically designed to suit the unique requirements of industrial, utility, and transmission applications. Customizing GIS is a common practice for ensuring that the switchgear performs optimally in specific use cases while meeting safety, efficiency, and space requirements. If you have a specific operational need, the customization options for GIS are flexible enough to adapt.

Gas Insulated Switchgear (GIS) typically uses insulating gases to provide high dielectric strength and prevent electrical arcing in the switchgear. The most commonly used gases in GIS are SF6 (Sulfur Hexafluoride) and alternative gases that are more environmentally friendly. Let’s go over the different types of gases used in GIS and the environmental considerations for each:

Usage: SF6 is the most widely used gas in GIS due to its superior dielectric properties and arc-quenching capabilities. It provides excellent insulation and is effective in preventing electrical breakdowns in high-voltage systems.

Environmental Considerations:

Usage: Air-insulated switchgear (AIS) typically uses ambient air as the insulation medium. However, for GIS, clean air or dry air is increasingly being used as an alternative to SF6. This is especially true for systems where a reduced environmental impact is a priority.

Environmental Considerations:

Availability: Clean air is abundant, inexpensive, and easy to manage, making it a sustainable alternative. However, it is still relatively new in large-scale GIS applications, and its use is primarily seen in lower-voltage systems (up to 72.5 kV).

Usage: Gases like C6HFN (fluoronitrile), which is a type of fluoronitrile-based gas, have emerged as potential alternatives to SF6. They are typically used in combination with other gases such as CO₂ to achieve the desired dielectric strength for GIS systems.

Environmental Considerations:

Availability: Fluoronitrile-based gases are still relatively new in the market, and while they show promise, their use is not yet as widespread as SF6. Companies like 3M and General Electric are leading efforts to incorporate these gases into GIS and other high-voltage equipment.

Usage: CO₂ is sometimes used in hybrid GIS designs, often mixed with other gases, such as fluoronitriles or clean air, to provide adequate insulation and arc-quenching capabilities.

Environmental Considerations:

Other gases such as gaseous mixtures or fluorinated esters are being researched and trialed as potential alternatives to SF6 in GIS. These gases may offer a balance between effective insulation, low GWP, and compatibility with existing GIS technology.

Environmental Considerations:

SF6: Highly effective for GIS insulation but has a very high global warming potential (GWP). Regulatory pressure is increasing to reduce its use and replace it with lower-GWP alternatives.

Clean Air: Zero GWP, environmentally friendly, and non-toxic, but requires large-scale infrastructure and precise moisture control. Primarily used in medium-voltage GIS.

Fluoronitrile-Based Gases: Lower GWP, biodegradable, and non-toxic, making them a promising alternative to SF6. Their use is still growing and typically suited for high-voltage GIS.

CO₂: Zero ODP and low GWP, but typically used in hybrid systems with other gases. Safe in typical concentrations but needs careful management.

Other Fluorinated Gases: Gases like fluorinated esters or mixtures with CO₂ are under development as low-impact alternatives, and offer promising environmental benefits.

The trend in GIS design is moving toward environmentally friendlier insulating gases, primarily to reduce the environmental impact of SF6. Alternatives like clean air, fluoronitrile-based gases, and CO₂ mixtures offer reduced GWP and better sustainability profiles. However, there are still challenges in achieving the same level of dielectric strength and performance as SF6, which is why SF6 is still the most widely used gas in GIS, though alternatives are gaining traction with advancing technology and regulations.

The short-circuit withstand strength of Gas Insulated Switchgear (GIS) refers to the ability of the switchgear to withstand and interrupt the fault current during a short-circuit event without being damaged. This is a critical characteristic in ensuring the reliability and safety of the power system, as GIS systems are often deployed in high-voltage transmission and distribution networks where fault conditions can occur.

Rated Short-Circuit Withstand Strength:

Typical Ratings:

Break Time:

GIS systems are designed and tested to comply with various international standards related to electrical safety, performance, and environmental impact. Some key standards that address short-circuit withstand strength and related parameters include:

To ensure compliance with these international standards, GIS manufacturers perform several rigorous tests to validate the short-circuit withstand strength:

The IP (Ingress Protection) rating of Gas Insulated Switchgear (GIS) is a measure of its ability to protect against the ingress of solid objects (like dust) and liquids (such as water). The IP rating system is defined by the IEC 60529 standard, which assigns a two-digit code to indicate the level of protection.

First Digit (Solid Object Protection): The first digit indicates the level of protection against the ingress of solid objects, such as dust, debris, or fingers.

Second Digit (Liquid Protection): The second digit represents the protection against the ingress of liquids, such as water.

For Gas Insulated Switchgear (GIS), the typical IP rating is IP67 or IP68.

IP67: This rating indicates the following:

IP68: Some GIS systems designed for more challenging environmental conditions may have an IP68 rating:

This guidebook serves as an extensive resource for professionals, engineers, and researchers interested in Gas Insulated Switchgear (GIS). It covers the fundamental principles, technology advancements, design considerations, operational challenges, and environmental impacts of Gas Insulated Switchgear (GIS). Through detailed explanations, case studies, and practical insights, readers will gain a deep understanding of Gas Insulated Switchgear (GIS) technology and its applications in modern power.

Power transformers are essential components of electrical distribution systems, responsible for safely stepping voltages up or down to ensure efficient power delivery. While generally reliable,

Gas Insulated Switchgear (GIS) Blogs

Power transformers are essential components of electrical distribution systems, responsible

Transformers are critical components in power systems, designed for long-term

Transformers are essential components of modern power distribution systems. Their

Have questions about our products or services? Interested in collaborating with us? Fill out the form, and a member of our team will get back to you promptly.

Tel / WhatsApp

info@taishantransformer.com

No. 367 of Tianzhufeng Road, Taian, Shandong, China,271000

Shandong Luneng Mount Tai Electrical Equipment Co.,Ltd., a subsidiary of Taishan Group, has 60 years of expertise in power equipment production, manufacturing, and R&D. It oversees five subsidiaries: Taian Taishan Electric Co., Ltd., Taian Taishan High Voltage Switch Co., Ltd., Shandong Luneng Mount Tai Electrical Equipment Co.,Ltd., Taian Huaneng Insulation Material Co., Ltd.,.

We're here for you !

let's Talk about your Project!