The cost of a transformer can vary widely depending on its type, size, voltage rating, and application. Whether you're sourcing a small distribution transformer or a large power transformer for an industrial or utility-scale project, understanding the key cost factors is essential for planning and budgeting.

What Are the Main Types of Transformers and Their Price Ranges?

Choosing the right transformer for your project can be overwhelming without understanding the range of types and their corresponding prices. One of the most common mistakes in transformer procurement is underestimating lifecycle costs or selecting a type that doesn’t match the application—leading to excessive energy loss, frequent maintenance, or premature failure. To avoid these costly errors, it’s essential to understand the different categories of transformers, their core features, and typical market price ranges. In this article, we’ll break down the most widely used transformer types in power systems and industry, and provide realistic pricing benchmarks to help guide procurement, budgeting, and technical decisions.

The main types of transformers include power transformers, distribution transformers, dry-type transformers, oil-immersed transformers, autotransformers, and specialty transformers (such as rectifier or isolation transformers). Prices range widely depending on size (kVA/MVA), voltage level, cooling type, and application—from around \$1,000 for small distribution units to over \$1 million for high-capacity power transformers.

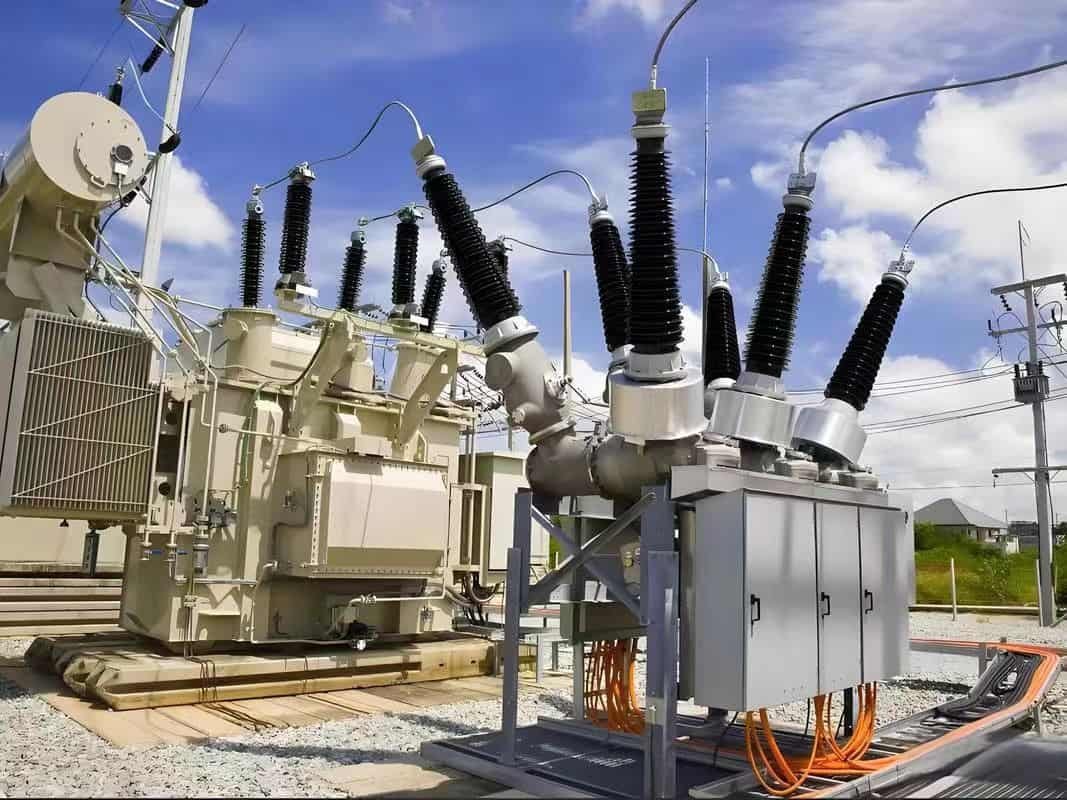

Whether you're designing a substation, upgrading a factory, or planning a utility-scale project, understanding transformer types and prices is critical to making informed decisions. Below, we explore each major type, typical specifications, and real-world cost ranges.

Transformer prices vary greatly based on type, size, and voltage level.True

Transformer costs are influenced by cooling method, capacity, insulation, core materials, and application complexity.

All transformers cost about the same regardless of application.False

Large power transformers can cost over 100 times more than small distribution units due to size, insulation, and engineering demands.

Overview of Main Transformer Types and Their Costs

| Transformer Type | Application | Typical Rating | Estimated Price Range (USD) |

|---|---|---|---|

| Power Transformer | Transmission substations, power plants | 2.5–1,000 MVA | \$50,000 – \$2,000,000+ |

| Distribution Transformer | Utility pole, pad-mounted, neighborhood use | 25–2,500 kVA | \$1,000 – \$25,000 |

| Dry-Type Transformer | Indoor commercial, industrial, clean zones | 100–2,500 kVA | \$3,000 – \$50,000 |

| Oil-Immersed Transformer | Outdoor, high-capacity industrial/utility | 50 kVA – 500 MVA | \$2,000 – \$1,000,000 |

| Autotransformer | Grid voltage interface, regional transmission | 10–800 MVA | \$30,000 – \$1,500,000 |

| Rectifier Transformer | Electrolysis, furnaces, mining | Custom (500 kVA – 100 MVA) | \$15,000 – \$800,000+ |

| Isolation Transformer | Hospitals, data centers, sensitive devices | 1–500 kVA | \$300 – \$20,000 |

1. Power Transformers

| Use Case | Transmission Substations, Generator Step-Up |

|---|---|

| Voltage Range | 66 kV – 765 kV |

| Capacity | 2.5 MVA to 1,000 MVA |

| Cooling | Oil-immersed (ONAN, ONAF, OFAF) |

| Typical Price | \$150,000 – \$2,000,000+ depending on specs |

Power transformers are custom-engineered high-voltage units used to interconnect power plants and transmission grids. Prices are influenced by winding material, cooling system, tap changer design, insulation class, and shipping logistics.

2. Distribution Transformers

| Use Case | Utilities, Urban Grids, Rural Electrification |

|---|---|

| Voltage Range | 11 kV / 6.6 kV → 400/230 V |

| Capacity | 25 kVA to 2,500 kVA |

| Installation Type | Pole-mounted, pad-mounted, kiosk type |

| Typical Price | \$1,000 – \$25,000 |

These are the most common transformers globally, used in local distribution networks. Smaller units for rural use cost less, while urban units with anti-theft features or built-in protection command higher prices.

3. Dry-Type Transformers

| Use Case | Indoor Environments, Hospitals, Schools, Industry |

|---|---|

| Voltage Range | 400 V to 11 kV |

| Cooling | AN, AF, VPI-encapsulated |

| Capacity | 100 – 2,500 kVA |

| Typical Price | \$3,000 – \$50,000 |

These fire-resistant, non-oil transformers are ideal for indoor applications. Their pricing depends on encapsulation type, insulation class (F or H), and harmonic suppression design.

4. Oil-Immersed Transformers

| Use Case | Outdoor Installations, Industrial Grids |

|---|---|

| Voltage Range | 6.6 kV – 220 kV |

| Capacity | 50 kVA – 500 MVA |

| Typical Price | \$2,000 – \$1,000,000 |

Oil-immersed transformers dominate heavy-duty environments and utility installations due to their durability and cooling efficiency. Prices increase sharply with higher insulation levels, tank pressure ratings, and cooling system types.

5. Autotransformers

| Use Case | Regional Grid Interface, Step-Down/Up in EHV |

|---|---|

| Voltage Range | 400/220/132 kV |

| Capacity | 10 – 800 MVA |

| Typical Price | \$30,000 – \$1,500,000 |

Autotransformers use shared windings, offering cost and weight advantages over two-winding transformers but need enhanced protection systems. They're often used in regional transmission stations and long-haul grids.

6. Rectifier Transformers

| Use Case | Electrochemical, Steel Plants, Smelters, DC Loads |

|---|---|

| Voltage Range | Custom AC inputs with DC output integration |

| Capacity | 500 kVA – 100 MVA |

| Typical Price | \$15,000 – \$800,000 |

Rectifier transformers serve DC load applications, often paired with silicon-controlled rectifiers (SCRs) and need robust design for non-linear loads. Prices reflect custom windings and harmonic mitigation features.

7. Isolation Transformers

| Use Case | Sensitive Loads (Hospitals, Data Centers) |

|---|---|

| Voltage Range | 110/220/400 V |

| Capacity | 1 – 500 kVA |

| Typical Price | \$300 – \$20,000 |

Used to decouple sensitive equipment from noisy or dangerous power sources. These transformers are critical for medical, telecom, and IT applications, and often include EMI filters and surge protectors.

Transformer Price Influencing Factors

| Factor | Impact on Price |

|---|---|

| MVA/kVA Rating | Higher rating = higher core, copper = more cost |

| Voltage Class | Insulation, bushing design, surge protection |

| Cooling System | Dry (cheaper) vs OFWF or ONAF (costlier) |

| Protection Features | Built-in fuses, OLTCs, surge arresters increase cost |

| Custom Design | Custom voltages, enclosures, footprints = premium price |

| Compliance Standards | IEC, ANSI, BIS, CSA affect design, cost, and approval |

How Does Capacity (kVA or MVA) Affect Transformer Price?

Transformer procurement can be one of the most expensive line items in any electrical infrastructure project. Yet a major point of confusion for buyers and planners is how capacity ratings—expressed in kVA or MVA—directly affect the price of a transformer. Underestimating or overestimating this factor can lead to disastrous outcomes: from project budget overruns to overloaded systems or underutilized equipment. Understanding the correlation between transformer capacity and cost is critical to accurate budgeting, proper sizing, and system reliability. This article provides a detailed, data-driven explanation of how transformer capacity impacts pricing—and what hidden cost drivers exist behind the rating.

Transformer capacity, measured in kilovolt-amperes (kVA) or megavolt-amperes (MVA), has a direct and exponential effect on price. As capacity increases, the size of the core, windings, insulation, cooling systems, and structural components also scales up—raising material costs, engineering complexity, and logistics expenses. Generally, doubling the capacity can increase the price by 1.6–1.8× depending on voltage level, design, and features.

Proper transformer sizing is not only a technical issue but also a financial one. Below we explore in detail how different capacity tiers impact cost, supported by technical comparisons, pricing charts, and real-world case data.

Transformer price increases with higher kVA or MVA capacity.True

Larger capacity transformers require more copper, steel, insulation, and cooling systems, driving up costs.

A 2,000 kVA transformer costs exactly twice as much as a 1,000 kVA transformer.False

Transformer price increases are nonlinear due to material, design, and handling complexities.

How Capacity Drives Transformer Price

| Transformer Capacity | Voltage Class | Typical Cooling Type | Estimated Price Range (USD) |

|---|---|---|---|

| 25 kVA | 11 kV / 0.4 kV | ONAN (Oil Natural) | \$1,000 – \$1,500 |

| 100 kVA | 11 kV / 0.4 kV | ONAN | \$2,000 – \$3,500 |

| 500 kVA | 11 kV / 0.4 kV | ONAN or ONAF | \$5,000 – \$10,000 |

| 1,000 kVA (1 MVA) | 11/33 kV | ONAF | \$10,000 – \$18,000 |

| 2,500 kVA (2.5 MVA) | 33 kV / 0.4 kV | OFAF | \$25,000 – \$50,000 |

| 10 MVA | 66/132 kV | OFAF or OFWF | \$80,000 – \$180,000 |

| 100 MVA | 220 kV | OFWF, OLTC | \$400,000 – \$900,000 |

| 500+ MVA | 400/765 kV | OFWF, high-end designs | \$1.2 million – \$2.5 million |

Note: These prices are indicative for standard designs and may vary based on custom specs, certifications, and market conditions.

Price Growth Pattern: Nonlinear Scaling with Capacity

Chart: Transformer Price vs Capacity (Log Scale)

| Capacity (kVA/MVA) | Approx. Multiplier from Base (25 kVA) |

|---|---|

| 25 kVA | 1× |

| 100 kVA | 2.2× |

| 500 kVA | 6–7× |

| 1,000 kVA | 10–12× |

| 2,500 kVA | 25–35× |

| 10 MVA | 80–100× |

| 100 MVA | 300–400× |

The price curve is logarithmic, not linear—as capacity grows, complexity increases disproportionately. Key drivers include:

- Copper volume and core steel mass

- Bushing and winding insulation size

- Tank construction and pressure rating

- Cooling systems (air vs oil vs water)

- Transport complexity and installation logistics

Technical Factors Influencing Price with Capacity

| Technical Element | Low Capacity Transformer (≤100 kVA) | High Capacity Transformer (≥10 MVA) |

|---|---|---|

| Core & Coil Materials | Minimal copper and CRGO steel | Massive core with tightly wound HV windings |

| Cooling System | Natural air/oil cooling (ONAN) | Forced oil and water cooling (OFAF, OFWF) |

| Insulation Class | Basic cellulose and pressboard | High-temp paper, pressboard, synthetic films |

| Tap Changers | Often fixed-tap or off-load | On-load tap changers (OLTC), automated controls |

| Protection | Basic fuse or breaker | Integrated relay systems, surge arresters |

| Testing & Certification | Factory type test | Full routine + special tests (impulse, heat run) |

Real-World Example: Industrial Plant Installation

| Scenario | Option A | Option B |

|---|---|---|

| Required Capacity | 1,000 kVA | 2,500 kVA |

| Voltage Level | 11 kV/400 V | 33 kV/400 V |

| Transformer Type | Oil-immersed, ONAN | Oil-immersed, OFAF |

| Base Price | \~\$15,000 | \~\$38,000 |

| Price per kVA | \~\$15/kVA | \~\$15.2/kVA (due to complexity) |

| Footprint | 1.5 m² | 4 m² |

As capacity scales up, both total price and cost per kVA increase slightly due to higher design complexity and physical requirements.

Additional Cost Factors Beyond kVA/MVA

| Factor | Price Impact |

|---|---|

| Voltage class (≥132 kV) | Higher insulation, larger bushings |

| OLTC requirement | Adds \$10,000–\$50,000 depending on tap count and controls |

| Cooling upgrades (OFAF, OFWF) | Adds 10%–40% depending on radiator and pump systems |

| Standard vs Custom Design | Custom footprint or spec raises price by 20%–100% |

| Certification (IEC, ANSI, BIS) | Testing, design modification, paperwork |

What Role Do Voltage Ratings Play in Pricing?

When purchasing a transformer, many buyers focus solely on capacity (kVA or MVA), but voltage rating is equally crucial and often the hidden driver of major cost differences. Choosing a transformer with the wrong voltage rating for your system can lead to over-engineering (wasting money) or dangerous underperformance (risking equipment failure and grid instability). Voltage rating affects not just the transformer’s electrical design but also its physical construction, insulation requirements, and protection systems—all of which significantly influence the final price. In this article, we’ll explore how voltage ratings affect transformer pricing and why higher voltages come with both performance advantages and increased costs.

Voltage ratings in transformers have a significant impact on pricing because higher voltage levels require stronger insulation, larger bushings, more robust clearances, and enhanced testing standards. As voltage class increases—from low voltage (<1.1 kV) to medium (up to 33 kV), high (up to 220 kV), and extra-high voltage (400+ kV)—transformer design complexity and manufacturing costs rise sharply.

Understanding how voltage affects transformer cost helps specifiers, procurement officers, and engineers avoid over- or under-investing in transformer infrastructure. Below, we break down pricing trends, design challenges, and cost implications across voltage classes.

Higher voltage ratings lead to more expensive transformer designs.True

More insulation, larger clearances, stronger tank structures, and higher test standards are required for high-voltage transformers.

Voltage rating has little to no effect on transformer price compared to capacity.False

Voltage rating significantly influences price due to additional insulation, material, and engineering requirements.

Voltage Class vs Price: Summary Comparison

| Voltage Class | Typical Use | Key Design Factors | Estimated Price Impact |

|---|---|---|---|

| Low Voltage (≤1.1 kV) | Internal circuits, isolation transformers | Minimal insulation, simple windings | \$300 – \$2,000 |

| Medium Voltage (1.1–33 kV) | Distribution transformers, factories | Oil or dry-type, standard bushings | \$1,000 – \$50,000 |

| High Voltage (33–132 kV) | Substations, large industry | Advanced cooling, oil-immersed, OLTC | \$20,000 – \$500,000 |

| Extra-High Voltage (220–400 kV) | Utility transmission, regional grid | Large core, special bushings, radiators | \$200,000 – \$2,000,000+ |

| Ultra-High Voltage (500+ kV) | Inter-country or grid backbone systems | Highest insulation, custom engineering | \$1M – \$5M+ |

How Voltage Increases Drive Price

| Factor Influenced by Voltage | Description | Cost Impact |

|---|---|---|

| Insulation Requirements | Higher voltage = thicker insulation, special dielectric materials | Adds 10%–50% or more |

| Bushing Design | Higher voltages need porcelain or composite bushings rated for surge withstand | Adds \$5,000 – \$100,000+ |

| Creepage and Clearance Distances | Larger air/oil gaps between windings and core for higher voltages | Larger tanks = higher material cost |

| Testing Standards | Higher voltage classes undergo lightning impulse, heat run, partial discharge | Adds testing cost and engineering time |

| Cooling Systems | High-voltage transformers require better heat dissipation (OFAF, OFWF, radiators) | Increases mechanical and electrical design cost |

Example: 1 MVA Transformer at Different Voltage Ratings

| Voltage Rating | Insulation Level | Cooling | Estimated Cost (USD) |

|---|---|---|---|

| 11 kV / 400 V | Standard oil-paper | ONAN | \$10,000 – \$14,000 |

| 33 kV / 400 V | Medium insulation | ONAN or ONAF | \$15,000 – \$22,000 |

| 66 kV / 400 V | High-grade insulation | ONAF or OFAF | \$30,000 – \$45,000 |

| 132 kV / 400 V | Advanced design, OLTC | OFAF | \$60,000 – \$90,000 |

| 220 kV / 400 V | High-end insulation | OFWF + OLTC | \$100,000 – \$180,000 |

As shown above, a transformer of the same capacity (1 MVA) can vary more than 10× in price simply based on the voltage rating and insulation class.

Price Growth vs Voltage Class (Chart Summary)

| Voltage Level | Relative Price Growth |

|---|---|

| 1.1 kV | 1× |

| 11 kV | 1.3× |

| 33 kV | 2× |

| 66 kV | 3.5× |

| 132 kV | 6× |

| 220 kV | 9× |

| 400 kV+ | 12–20× |

Price grows non-linearly as voltage increases due to compounding design and manufacturing challenges.

Engineering Factors Unique to High-Voltage Transformers

| Design Aspect | Low Voltage | High Voltage (220–400 kV) |

|---|---|---|

| Windings | Single or dual | Multiple winding layers, axial support |

| Core Type | Shell or simple core | Advanced laminated CRGO cores |

| Tank Construction | Light steel enclosure | Heavy welded tank, reinforced |

| Dielectric Fluids | Mineral oil | High dielectric oil, ester-based options |

| Monitoring Equipment | Optional | Mandatory (RTDs, Buchholz, SCADA, etc.) |

High-voltage transformers often require custom site preparation, rigging plans, and utility coordination, which also increases project cost.

Are Custom-Built Transformers More Expensive?

Custom-built transformers are often essential when standard models can’t meet specific technical, spatial, or regulatory needs. But one of the most common concerns buyers face is cost: How much more expensive is a custom transformer compared to a standard one? The answer isn’t always straightforward. While customization offers significant advantages—like footprint optimization, performance tuning, or environmental adaptation—it comes at a price. Unfamiliarity with the cost structure can lead to sticker shock, delayed budgeting, or poor design decisions. In this article, we explain how custom features affect transformer pricing and provide clear benchmarks to help you make cost-effective, performance-optimized choices.

Yes, custom-built transformers are generally more expensive than standard models due to specialized engineering, design validation, low-volume production, non-standard components, and increased testing requirements. On average, a custom transformer can cost 20%–100% more than a standard unit of the same capacity and voltage class, depending on the complexity of customization.

Whether you're planning a new substation, fitting a transformer into a space-restricted facility, or designing a high-performance renewable grid component, understanding the cost drivers behind customization helps you manage both technical and financial aspects with confidence.

Custom-built transformers typically cost more than standard units.True

Custom designs involve extra engineering, non-standard parts, and extended testing, which increase the overall price.

Custom transformers are cheaper because they’re made for one specific job.False

While custom units are built for specific requirements, their lack of mass production and added engineering raise costs.

Why Custom-Built Transformers Cost More

| Cost Driver | Description |

|---|---|

| Engineering Design | Additional hours required for custom electrical and mechanical calculations |

| Non-Standard Dimensions | Altered tank size, bushing positions, or enclosure materials |

| Unique Voltage/Tap Range | Non-catalog voltage combinations or tap changer configurations |

| Cooling Modifications | Custom radiator, fan placement, or fluid specifications (OFAF, ester, etc.) |

| Control Integration | Special relays, sensors, SCADA/IoT connectivity |

| Compliance & Testing | IEC/ANSI deviations, client factory witness tests, type testing |

| Lower Production Volume | No economy of scale; each unit is a one-off |

| Extended Delivery & Approvals | Lead time for design reviews, drawing approval, and customization delays |

Price Comparison: Standard vs Custom Transformer

| Parameter | Standard Transformer | Custom Transformer |

|---|---|---|

| Capacity | 1,000 kVA | 1,000 kVA |

| Voltage | 11 kV / 400 V | 13.2 kV / 380 V |

| Enclosure | Standard IP23 Outdoor | Stainless steel IP55 with vents |

| Cooling | ONAN | OFAF with side-mounted radiators |

| Tap Changer | Off-load ±5% | On-load ±10%, 17 taps |

| Protection | Basic relay + Buchholz | SCADA-integrated with RTDs + gas relay |

| Price Estimate (USD) | \$15,000 – \$18,000 | \$25,000 – \$35,000 |

| Price Increase | – | \~70% higher |

This example demonstrates how customization for enclosure, voltage rating, and controls can nearly double the price.

Customization vs Capacity Price Curve

| Customization Level | Typical Cost Impact |

|---|---|

| Basic (mounting, terminals) | +10%–20% |

| Moderate (voltage/taps) | +20%–50% |

| Advanced (cooling, SCADA) | +50%–100% or more |

| Mission-Critical (nuclear, offshore) | +200%–300%+ |

As complexity increases, the cost-per-kVA also increases, especially for smaller units where fixed costs are spread over fewer kilovolt-amperes.

Examples of Common Custom Transformer Scenarios

| Application | Customization Needs |

|---|---|

| Data Centers | Low harmonic design, shielded isolation, copper winding |

| Tunnels & Subways | Compact size, dry-type, IP55 enclosures |

| Marine Platforms | Corrosion-proof casing, vibration isolation, Lloyd's approval |

| Solar & Wind Systems | Pad/skid-mounted, inverter integration, dual-winding design |

| Retrofits in Old Plants | Size-fit replacements, matching legacy voltages/taps |

Each scenario presents a specific engineering challenge that increases cost but also improves performance and safety.

Factors That Can Help Optimize Cost

| Strategy | Cost Benefit |

|---|---|

| Use of semi-standard components | Reduces fabrication time and sourcing risk |

| Early design consultation | Avoids last-minute redesign or overengineering |

| Batch procurement (≥2 units) | Reduces setup cost and increases manufacturing efficiency |

| Material substitution | Replace copper with aluminum where appropriate |

| Selecting flexible core dimensions | Enables reuse of existing core sizes and reduces tooling changes |

Not all customizations need to be expensive—smart engineering can balance flexibility with cost-effectiveness.

What Other Costs Should Be Considered When Purchasing a Transformer?

When buying a transformer, most buyers focus only on the upfront purchase price—but this is just the tip of the iceberg. Failing to account for installation, operational, and lifecycle costs can lead to severe budget overruns, long-term inefficiencies, and costly system failures. Transformers are capital-intensive, long-lifespan assets, and their total cost of ownership (TCO) includes many hidden expenses that must be addressed during planning and procurement. In this article, we will break down all the other essential costs you need to consider beyond the sticker price to help ensure you make a cost-effective and operationally sound investment.

In addition to the purchase price, transformer ownership includes significant costs related to site preparation, transportation, installation, protection devices, energy losses, maintenance, monitoring systems, insurance, environmental compliance, and eventual decommissioning. These can add 30%–200% to the initial capital cost over the transformer's life.

Ignoring these costs may result in incomplete budgeting and unexpected future expenditures. Below is a comprehensive breakdown of every major cost category to consider when planning for transformer acquisition and deployment.

Transformer ownership involves costs beyond just the initial purchase price.True

Installation, energy losses, protection, and maintenance add to total ownership costs over the equipment's lifetime.

Transformer cost ends once the unit is purchased.False

A transformer’s true cost includes installation, operation, and long-term maintenance.

Total Transformer Ownership Cost Breakdown

| Cost Category | Typical Percentage of TCO | Description |

|---|---|---|

| Capital Cost (Base Price) | 30%–60% | Manufacturer cost for the physical transformer unit |

| Transportation & Handling | 5%–10% | Logistics, crating, site unloading, crane or lift equipment |

| Site Preparation | 3%–7% | Civil works, foundation, fencing, concrete pads, oil containment trays |

| Installation & Commissioning | 5%–15% | Electrical hookup, oil filling, tap setting, testing, and energization |

| Protection & Accessories | 5%–10% | CTs, VTs, surge arresters, OLTCs, bushings, relays, and circuit breakers |

| Energy Losses (No-load & Load) | 10%–30% over life | Iron/core loss and copper losses during regular operation |

| Cooling & Monitoring Systems | 3%–8% | Radiators, fans, sensors, SCADA, Buchholz, temperature & gas relays |

| Maintenance & Servicing | 5%–15% | Oil testing, bushing inspection, relay calibration, periodic overhauls |

| Regulatory & Environmental | 2%–5% | Oil spill containment, emissions, acoustic controls |

| Insurance & Safety | 1%–3% per year | Fire insurance, explosion risk, liability, compliance certifications |

| End-of-Life Disposal | 2%–6% | Oil draining, scrap handling, recycling, hazardous material removal |

1. Energy Losses: The Hidden Giant

| Loss Type | Typical Impact | Estimated Cost (20-Year Life) |

|---|---|---|

| Core Loss (No-Load) | 0.3–2% of rated power, 24/7 | \$5,000 – \$50,000+ depending on rating |

| Copper Loss (Load Loss) | Varies with usage pattern | \$10,000 – \$200,000+ for large units |

Energy losses translate to ongoing utility charges, and low-loss transformers—though more expensive upfront—can save hundreds of thousands in lifetime cost.

2. Installation & Site Infrastructure

| Component | Estimated Cost Range (USD) |

|---|---|

| Concrete Pad/Foundation | \$1,000 – \$25,000 |

| Oil Containment Pit | \$3,000 – \$10,000 |

| Cable Trenching & Ducts | \$2,000 – \$20,000 |

| Earthing/Grounding System | \$500 – \$5,000 |

| Commissioning Labor | \$1,000 – \$10,000 |

Costs vary depending on voltage class, local labor rates, and site conditions (e.g., flood risk, seismic zone, etc.).

3. Cooling and Monitoring Systems

| System | Function | Typical Additional Cost |

|---|---|---|

| Radiator Bank (ONAF/OFAF) | Dissipates heat via forced airflow | \$5,000 – \$50,000 |

| Oil Pumps (OFWF systems) | Circulates oil in high-MVA units | \$10,000 – \$60,000 |

| Monitoring Sensors (RTDs) | Detect core, winding, and oil temps | \$1,000 – \$10,000 |

| SCADA/IoT Interface | Enables real-time remote monitoring | \$5,000 – \$25,000 |

High-value installations benefit from predictive monitoring that prevents unplanned outages.

4. Routine Maintenance & Servicing

| Activity | Frequency | Estimated Cost/Visit |

|---|---|---|

| Oil Sampling & DGA | Yearly | \$200 – \$500 |

| Insulation Resistance Test | 3–5 years | \$500 – \$1,000 |

| Tap Changer Maintenance | 3–5 years | \$1,000 – \$3,000 |

| Full Overhaul | 10–15 years | \$10,000 – \$50,000+ |

Neglected maintenance leads to accelerated aging, failures, and premature replacement.

5. Environmental & Safety Compliance

| Requirement | Purpose | Estimated Cost |

|---|---|---|

| Fire Suppression Systems | Prevent transformer oil fires | \$5,000 – \$20,000 |

| Acoustic Enclosure | Noise reduction near residential areas | \$3,000 – \$30,000 |

| Oil Spill Containment | Complies with EPA/BIS/IS regulations | \$2,000 – \$10,000 |

| Decommissioning & Disposal | Required at end-of-life | \$2,000 – \$15,000+ |

These are often required by local regulations and utility grid codes.

Total Cost of Ownership: Sample Calculation (1 MVA, 11 kV/0.4 kV Unit)

| Cost Item | Estimated Value (USD) |

|---|---|

| Capital Cost (Transformer) | \$15,000 |

| Transportation & Site Works | \$8,000 |

| Installation & Commissioning | \$6,000 |

| Accessories & Protection | \$4,000 |

| Energy Losses (20 yrs) | \$35,000 |

| Maintenance (20 yrs) | \$10,000 |

| Monitoring/SCADA Integration | \$7,000 |

| Disposal & End-of-Life Costs | \$3,000 |

| Total Estimated TCO | \$88,000 |

Despite the \$15,000 base price, the true ownership cost exceeds 5× that figure over the transformer’s life.

What Are Typical Transformer Price Examples for Different Use Cases?

Transformer prices vary not just by capacity or voltage—but significantly by use case. The application determines everything from the required cooling system to insulation class, monitoring devices, environmental protection, and even enclosure type. A transformer that serves a small residential neighborhood may cost only a few thousand dollars, while one designed for a renewable energy plant, steel mill, or national grid substation can cost millions. If you’re budgeting for a specific sector or project, it’s essential to understand typical price ranges for that exact application. This article presents real-world price benchmarks for various transformer use cases, helping buyers make informed and accurate purchasing decisions.

Typical transformer prices vary by application—from as low as \$1,000 for small pole-mounted units to over \$2 million for high-capacity power transformers used in grid or industrial environments. Factors like voltage class, insulation, cooling type, environment, and monitoring systems drive these price differences.

If you’re involved in transformer specification, procurement, or capital budgeting, this breakdown by use case will help you set realistic expectations and avoid costly surprises.

Transformer prices are influenced by the specific application in which they are used.True

Different use cases require different insulation, enclosures, voltage ratings, and monitoring—affecting cost.

All transformers of the same capacity cost the same, regardless of application.False

The same capacity transformer may vary in price depending on its environment, voltage level, and engineering features.

1. Residential Distribution (Urban/Rural Neighborhood)

| Application | Pole-mounted or pad-mounted distribution transformer |

|---|---|

| Voltage | 11 kV / 400 V (LV) |

| Capacity | 25–250 kVA |

| Cooling Type | ONAN (oil-cooled), sealed |

| Enclosure | Standard or green box |

| Estimated Price | \$1,000 – \$8,000 USD |

Basic transformers used for feeding homes and small commercial buildings in urban or rural areas. Low cost, often procured in large batches by utilities.

2. Commercial Buildings (Malls, Offices, Hotels)

| Application | Dry-type indoor transformer for low-voltage power |

|---|---|

| Voltage | 11 kV / 415 V |

| Capacity | 250–1,000 kVA |

| Cooling Type | AN or AF (dry type, air cooled) |

| Enclosure | Indoor, IP23 or IP44 |

| Estimated Price | \$5,000 – \$25,000 USD |

These transformers are often enclosed in electrical rooms with building management system (BMS) integration and strict safety/fire codes.

3. Industrial Plants (Factories, Foundries, Refineries)

| Application | Heavy-duty step-down or isolation transformer |

|---|---|

| Voltage | 33 kV / 6.6 kV / 415 V |

| Capacity | 1,000–10,000 kVA (1–10 MVA) |

| Cooling Type | ONAF or OFAF |

| Enclosure | Outdoor, oil-cooled, with OLTC |

| Estimated Price | \$15,000 – \$250,000+ USD |

Industrial settings require rugged transformers with high fault tolerance, advanced protection, and robust cooling systems.

4. Renewable Energy (Solar or Wind Farms)

| Application | Pad-mounted step-up transformer near inverter or turbine |

|---|---|

| Voltage | 0.69 kV / 11–33 kV (LV to MV) |

| Capacity | 1,000–5,000 kVA (1–5 MVA) |

| Cooling Type | Oil-cooled, pad/skid-mounted |

| Special Features | Harmonic filtering, inverter compatibility |

| Estimated Price | \$20,000 – \$80,000 USD |

Renewables require special impedance, compact footprint, and often custom voltage matching for grid-tie compliance.

5. Data Centers and Critical Infrastructure

| Application | Dry-type isolation transformer with shielding |

|---|---|

| Voltage | 11 kV / 415 V or 480 V |

| Capacity | 500–2,500 kVA |

| Cooling Type | Dry type, forced-air |

| Special Features | EMI shielding, low inrush, temperature sensors |

| Estimated Price | \$10,000 – \$50,000+ USD |

Mission-critical facilities require transformers with tight voltage control, minimal harmonic distortion, and fire-safe designs.

6. Utility Transmission Substations (Grid Interface)

| Application | Generator step-up (GSU) or power transformer |

|---|---|

| Voltage | 132 kV / 33 kV or 400 kV / 132 kV |

| Capacity | 10–500 MVA |

| Cooling Type | OFAF / OFWF |

| Enclosure | Outdoor, high-insulation, heavy-duty |

| Estimated Price | \$200,000 – \$2,000,000+ USD |

These transformers are massive, highly engineered units with multiple bushings, OLTCs, and full-scale SCADA monitoring. They represent a major portion of substation project cost.

7. Railway Electrification / Metro Projects

| Application | Traction transformer or rectifier transformer |

|---|---|

| Voltage | 25 kV / 750 V DC or 25 kV / 1.5 kV AC |

| Capacity | 1–5 MVA |

| Cooling Type | Oil-cooled with tap changer |

| Special Features | Low harmonic, surge protection, rugged windings |

| Estimated Price | \$30,000 – \$150,000 USD |

Used in train stations, traction substations, and tunnels—often customized for vibration, moisture, and compact installation.

8. Healthcare / Hospitals

| Application | Medical-grade isolation transformer |

|---|---|

| Voltage | 415 V / 230 V (LV) |

| Capacity | 10–200 kVA |

| Cooling Type | Dry-type, shielded |

| Special Features | Leakage current limitation, alarm interfaces |

| Estimated Price | \$500 – \$10,000 USD |

These are specialized units often integrated into UPS systems and life-support applications, with strict electromagnetic and thermal performance.

Conclusion

Transformer costs vary significantly based on capacity, type, and technical specifications. Small transformers for residential or commercial use may cost a few thousand dollars, while utility-scale high-voltage transformers can reach several hundred thousand. When budgeting, it’s important to consider not just the initial cost but also transport, installation, and long-term maintenance. Accurate technical requirements and supplier comparisons are key to finding the best value.

FAQ

Q1: How much does a transformer cost?

A1: The cost of a transformer can vary widely depending on its type, size, and voltage rating:

Small residential transformers: $500 – $5,000

Medium-voltage distribution transformers: $5,000 – $50,000

Large power transformers (above 100 MVA): $100,000 – $2 million or more

Custom specifications, brand, and region can further affect pricing.

Q2: What factors influence the cost of a transformer?

A2: Key cost factors include:

Power rating (kVA/MVA)

Voltage level (low, medium, high)

Type (oil-immersed, dry-type, pad-mounted, pole-mounted)

Cooling system and efficiency rating

Custom features (e.g., smart monitoring, tap changers)

Installation location and logistics

Q3: How much does transformer installation cost?

A3: Installation costs can range from $1,000 to over $100,000, depending on:

Transformer size

Site preparation needs

Crane and labor requirements

Permitting and inspection fees

Protective equipment and grounding

Q4: Is it cheaper to repair or replace a transformer?

A4: Small transformers are often more economical to replace, while repairing large power transformers can be cost-effective if the core and windings are intact. A full cost-benefit analysis including downtime and future reliability should guide the decision.

Q5: Can transformer costs be reduced with standard models?

A5: Yes. Using standardized, off-the-shelf models typically reduces lead time and price. Custom-built transformers with special ratings or enclosures will generally cost more and require longer delivery.

References

"Transformer Cost Breakdown and Buying Guide" – https://www.transformertech.com/transformer-cost-guide – Transformer Tech

"Understanding Power Transformer Pricing" – https://www.powermag.com/transformer-pricing-factors – Power Magazine

"How Much Does a Transformer Cost?" – https://www.electrical4u.com/transformer-cost – Electrical4U

"Cost Estimation for Power Transformers" – https://www.researchgate.net/transformer-cost-analysis – ResearchGate

"Transformer Procurement and Pricing Trends" – https://www.sciencedirect.com/transformer-cost-factors – ScienceDirect

"Energy Central: Transformer Lifecycle Costs Explained" – https://www.energycentral.com/c/ee/transformer-cost-lifecycle – Energy Central

"Smart Grid News: Smart Transformers and Cost Trends" – https://www.smartgridnews.com/transformer-pricing-smart-grid – Smart Grid News

"PowerGrid: Installation and Purchase Costs of Transformers" – https://www.powergrid.com/transformer-costs-overview – PowerGrid