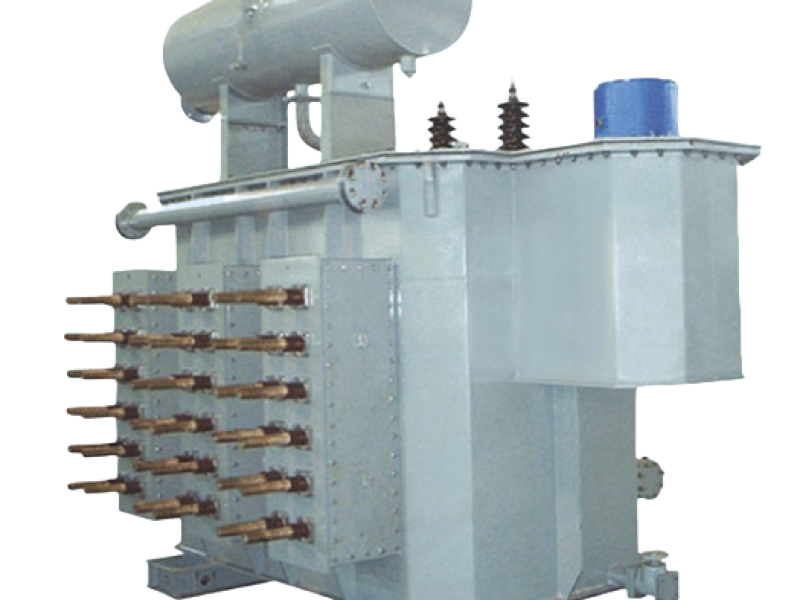

Electric furnace transformers are specialized transformers designed to provide power to various types of electric furnaces. Their primary function is to step down the high voltage from the power grid to the lower voltage and high current required by the furnace. Due to the operating characteristics of electric furnaces, these transformers must withstand harsh conditions such as high temperatures, large current surges, and frequent load fluctuations. Therefore, their design and manufacturing have specific requirements.

Applications:

Electric furnace transformers are widely used in metallurgy, chemical, machinery, and building materials industries for powering various electric furnaces in processes such as:

Trusted by world-class brands & organizations of all sizes

Key Characteristics of Electric Furnace Transformers:

Types of Electric Furnace Transformers:

Based on the type and application of the furnace, these transformers can be categorized into several types:

Operating Principle:

The operating principle is similar to other transformers, based on electromagnetic induction. When alternating current flows through the primary winding, it creates a changing magnetic field in the core. This field induces an electromotive force (EMF) in the secondary winding, achieving voltage transformation.

Key Differences from General Transformers:

Contact us to get detailed parameter information.

Main Components:

In response to fierce market competition and to meet customer demands, our company adheres to a market-oriented approach and a customer-centric philosophy. We have earned widespread recognition from our clients through efficient, comprehensive services and superior product quality.

We offer comprehensive after-sales services, including free guidance for installation and commissioning. After the product is operational, if the customer requires support, our service team will respond promptly:

Additionally, we have established a robust regular follow-up system. We conduct periodic written or on-site visits to monitor the performance of in-service products, ensuring our customers have continuous peace of mind.

Remote Technical Assistance

Our service team provides 24/7 online technical support, including video calls, troubleshooting guides, and documentation, ensuring immediate assistance regardless of time zones.

Detailed remote diagnostics can be conducted using customer-provided data or live visual inspections.

On-Site Support

For complex issues, we dispatch experienced technicians to the customer site promptly, adhering to the agreed international response timelines.

On-site services include installation guidance, commissioning, maintenance, and repairs.

Dedicated Service Representatives

Each international client is assigned a dedicated service representative to coordinate all aspects of after-sales support, including issue resolution and regular follow-ups.

Local Service Partnerships

We collaborate with certified local service partners in key markets to ensure faster response times and efficient support. These partners are fully trained in our products and processes to uphold our quality standards.

Regular Follow-Up Visits

Post-installation, we perform scheduled follow-up visits, either in person or virtually, to monitor product performance and address customer feedback. This proactive approach ensures optimal operation and customer satisfaction.

Why This Matters

Our comprehensive international service system combines swift response, advanced technical support, and localized expertise to provide our global clients with reliable and professional after-sales services. We are committed to building lasting partnerships through consistent support and excellence.

When purchasing an Electric furnace transformers, you may want to know the following questions & answers.

The maximum power rating of the electric furnace transformers we offer can vary significantly depending on the specifications and requirements of the electric furnace application. Typically, electric furnace transformers are designed to handle a wide range of power capacities, from industrial-grade furnaces to specialized high-capacity units.

Here are some typical ranges based on the application and furnace size:

Would you like further details on a specific range or for a particular type of electric furnace? I can provide more precise information based on the power rating, voltage requirements, and specific furnace application.

The voltage levels for the primary and secondary windings of electric furnace transformers depend on the specific requirements of the electric furnace and its application. The voltage levels are tailored to match the operational needs of the furnace, ensuring efficiency and safety during operation. Below are typical voltage ranges for both primary and secondary windings:

The primary voltage refers to the input voltage, which comes from the main electrical supply or grid. Electric furnace transformers are designed to handle high input voltages for large industrial operations.

Low Voltage Range:

Medium Voltage Range:

High Voltage Range:

Ultra High Voltage Range (less common, used in very large operations):

The secondary voltage is the output voltage delivered to the furnace, which is typically lower than the primary voltage. The secondary voltage depends on the type of furnace, the required heating power, and the specific furnace design.

Low Voltage Range:

Medium Voltage Range:

High Voltage Range:

Induction Furnaces:

Electric Arc Furnaces (EAF):

Adjustable Secondary Voltage: Some transformers allow for adjustable secondary voltages to optimize the furnace operation, depending on the material being melted or heated, which can be important for high-precision applications.

Multi-Tap Configurations: Transformers can also be designed with multi-tap secondary windings to provide flexibility in adjusting the output voltage to suit varying operational conditions.

The voltage levels often influence the cooling system design:

| Primary Voltage (kV) | Secondary Voltage (kV) |

|---|---|

| 0.38 kV – 0.69 kV | 0.4 kV – 6 kV |

| 3.3 kV – 6 kV | 1 kV – 6 kV |

| 10 kV – 36 kV | 1 kV – 6 kV |

| 36 kV – 72 kV (rare) | 6 kV – 36 kV |

The choice of voltage levels for both primary and secondary windings depends on:

Would you like more detailed technical specifications or assistance with selecting the correct transformer for a specific application?

Yes, electric furnace transformers can be designed to handle both AC (alternating current) and DC (direct current) applications, but the design and characteristics of the transformer will differ depending on the type of current required for the furnace.

Most electric furnace transformers are designed to handle AC applications, as alternating current is the most commonly used power source in industrial furnaces, including:

For AC applications, the transformer:

Some specialized furnaces use DC for specific heating applications, such as:

For DC applications, the transformer needs to be modified to accommodate the conversion from AC to DC:

AC to DC Conversion: To supply DC to a furnace, the AC voltage must first be rectified. This is usually done with a rectifier circuit (using diodes or thyristors) that converts the AC output of the transformer into DC.

DC Voltage Control: DC systems may require more precise control of voltage and current, which could involve additional components like voltage regulators or thyristor-based control circuits.

Transformer Design Considerations for DC:

Some modern electric furnace systems may feature hybrid designs, where both AC and DC can be used at different stages of the heating process, or where switching between AC and DC is possible based on specific needs (e.g., for energy efficiency, temperature control, or precision melting).

If you’re dealing with DC applications, we can design custom transformers that include the necessary rectification and control features for stable DC output, or we can assist with providing integrated solutions involving transformers and rectifiers. Let me know if you need further assistance!

The efficiency of electric furnace transformers depends on several factors, including the design, construction, and operating conditions. Generally, electric furnace transformers are designed to be highly efficient, but the exact efficiency can vary based on the transformer’s size, power rating, cooling method, and whether it’s designed for AC or DC applications.

Standard Efficiency Range:

Smaller Transformers (e.g., below 500 kVA):

Core Losses (Magnetic Losses):

Copper Losses (Resistive Losses):

Load Profile:

Cooling System:

Load Factor and Power Factor:

Magnetic Saturation:

For large, modern electric furnace transformers designed for high-power applications, efficiencies up to 99% are achievable under optimal load conditions. Some highly efficient designs used in critical industrial applications (e.g., steel production) may even approach 99.5%, but this is often seen in specialized, high-end equipment.

Oil-Immersed Transformers: These tend to have slightly better efficiency because of their superior cooling capabilities, which help maintain a lower operating temperature, minimizing losses.

Dry-Type Transformers: Typically used for smaller or indoor applications, dry-type transformers are generally slightly less efficient than oil-cooled transformers, especially at larger ratings. However, their efficiency can still be quite high, usually in the range of 95% – 98%.

Efficiency tends to decrease slightly at partial load (e.g., 50% load), as the no-load losses (core losses) remain constant while the load losses (copper losses) are reduced. To achieve the highest efficiency, transformers should ideally operate close to their rated capacity. However, high-quality transformers designed for furnace applications are typically optimized to minimize these losses across a wide range of operational loads.

| Transformer Rating | Typical Efficiency |

|---|---|

| < 500 kVA | 95% – 98% |

| 500 kVA – 5,000 kVA | 97% – 98% |

| 5,000 kVA – 20,000 kVA | 98% – 99% |

| > 20,000 kVA | 98% – 99%+ |

Our electric furnace transformers generally achieve efficiency ratings of 95% to 99% depending on the size and type. For larger furnaces (e.g., EAFs or induction furnaces), where power ratings exceed 5,000 kVA, efficiency can be as high as 99% or more under full load. High-quality materials, advanced cooling systems, and proper load management are key to maintaining these high-efficiency levels.

If you need more specific details or want to explore energy-saving options (like power factor correction or efficiency optimization), I can provide further technical assistance. Let me know how you would like to proceed!

Yes, our electric furnace transformers are designed and built to comply with a range of international standards to ensure high quality, safety, and performance. These standards are critical for ensuring that the transformers meet global expectations for safety, reliability, and operational efficiency. We adhere to well-established guidelines set by industry-leading organizations, including IEC, ANSI, and IEEE, among others. Below are the primary standards and certifications that our electric furnace transformers comply with:

The IEC is one of the most recognized international standardization bodies, and many of our transformers meet or exceed the relevant IEC standards, such as:

IEC 60076 – Power transformers

IEC 61378-1 – Converter transformers:

IEC 60529 – Degrees of protection provided by enclosures (IP Code):

IEC 60214 – On-load tap-changers:

For electric furnace transformers intended for use in the United States or for customers who require compliance with North American standards, we also follow ANSI standards. These include:

ANSI C57.12.00 – General requirements for liquid-immersed distribution, power, and regulating transformers:

ANSI C57.12.90 – Test code for liquid-immersed distribution, power, and regulating transformers:

ANSI C57.96 – Guide for liquid-immersed transformer installation:

IEEE standards are often used in conjunction with IEC and ANSI standards to address specific technical details, particularly in the fields of electrical power systems and transformer performance.

IEEE C57.12.00 – Standard for Standard General Requirements for Liquid-Immersed Distribution, Power, and Regulating Transformers:

IEEE C57.12.90 – Standard for Standard Test Code for Liquid-Immersed Distribution, Power, and Regulating Transformers:

IEEE 519 – Recommended Practices and Requirements for Harmonic Control in Electrical Power Systems:

ISO 9001: Quality management standards are often implemented throughout the manufacturing process to ensure consistency, high-quality production, and adherence to specifications for electric furnace transformers.

UL Certification: For markets in North America, transformers can be UL certified to meet safety standards for electrical equipment and components. This includes UL 1561 for dry-type transformers and UL 506 for general transformers used in industrial environments.

CE Marking: For the European market, transformers are CE marked, ensuring they conform to the relevant European Union directives regarding safety, EMC (electromagnetic compatibility), and environmental impact.

ISO 14001: Environmental management standards are also adhered to in the design and manufacturing process, ensuring that transformers meet environmental requirements such as minimizing energy consumption and reducing emissions during operation.

Electric furnace transformers often require custom designs based on factors like the furnace type (e.g., electric arc furnaces, induction furnaces, or resistance furnaces), power rating, and voltage levels. Our transformers are built to meet the specific demands of these applications, which could include special features such as:

Our electric furnace transformers are fully compliant with international standards such as:

These certifications and standards ensure that the transformers meet global safety, performance, and environmental requirements, making them suitable for deployment in industrial furnace applications worldwide. If you need more specific details or have additional certification requirements for a particular region or project, feel free to let me know!

The type of cooling system used in electric furnace transformers depends on the power rating, size, operational conditions, and the specific requirements of the furnace (e.g., induction furnaces, electric arc furnaces). The primary function of the cooling system is to prevent the transformer from overheating, especially given the high currents and power levels involved in furnace operations. The most common cooling methods are oil-cooled and air-cooled, but other advanced cooling systems may be used in specific applications.

Oil cooling is the most commonly used method for electric furnace transformers, especially for large power ratings and industrial applications, due to its high efficiency in managing the heat generated under heavy loads.

Air-cooled transformers, also known as dry-type transformers, are less common for electric furnace transformers, especially in larger-scale applications, but may still be used in specific scenarios.

In some very large transformers, particularly in high-power furnace applications, a hybrid cooling system combining forced air and oil cooling may be used.

For some of the highest power and most advanced furnace transformers, there are liquid immersion cooling systems that go beyond standard oil. These systems use synthetic or ester-based fluids that offer enhanced properties such as higher fire resistance, improved environmental sustainability, and better dielectric strength.

| Cooling Method | Applications | Advantages | Disadvantages |

|---|---|---|---|

| Oil-Cooled (Liquid-Immersed) | Large power transformers, high-power industrial applications (e.g., arc furnaces, induction furnaces) | High cooling efficiency, good for high power ratings, provides insulation | Risk of oil leakage, requires maintenance, larger size |

| Air-Cooled (Dry-Type) | Smaller power transformers, indoor applications | Compact, no oil leakage, maintenance-free | Lower cooling efficiency, limited to smaller transformers (typically <3,000 kVA) |

| Hybrid (Oil + Forced Air) | Very high-power transformers, extreme operational conditions | Enhanced cooling for high loads, better heat dissipation | More complex, higher cost |

| Advanced Liquid Immersion | High-power transformers, environmentally sensitive applications | Fire-resistant, environmentally friendly, high cooling capacity | Higher cost, requires specialized maintenance |

Let me know if you need more specific information or assistance in selecting the appropriate cooling system for a particular application.

Yes, we offer custom designs for electric furnace transformers to meet specific operational requirements. We understand that each industrial application has unique demands, particularly in high-power environments like electric arc furnaces (EAFs), induction furnaces, and other specialized furnace types. Our custom design services are tailored to meet these diverse needs, ensuring optimal performance, efficiency, and safety for your furnace operations.

We can work with you to design and manufacture transformers that are specifically suited to the following operational requirements:

Our approach to custom transformer design involves a collaborative process where we work closely with you to ensure the final product meets all operational requirements:

If you have specific requirements for your electric furnace transformer or need a detailed consultation for a custom design, please feel free to contact us. We are ready to discuss your project in detail and offer the best solution for your needs.

Safety is a critical consideration when designing and operating electric furnace transformers, given the high power, intense electrical currents, and harsh industrial environments involved in furnace operations. Our electric furnace transformers come with a wide range of safety features to protect both the equipment and the personnel working around it. Below are the key safety features integrated into our designs:

Our electric furnace transformers are designed in accordance with global safety standards, such as:

| Safety Feature | Description |

|---|---|

| Overload Protection | Protection against excessive loads using thermal relays and fuses. |

| Short-Circuit Protection | Short-circuit withstand capability, protection relays, circuit breakers. |

| Ground Fault Protection | Detection and disconnection in case of ground faults. |

| Surge Protection | Surge arresters to protect against voltage spikes. |

| Fire Protection | Fire-resistant oils, flameproof enclosures, and leak detection. |

| Thermal Protection | Temperature sensors, overload protection, and cooling system monitoring. |

| Insulation Protection | High-class insulation to withstand heat and high voltage. |

| Vibration Protection | Shock-absorbing mounts and vibration dampers for mechanical protection. |

| External Environment Protection | Corrosion-resistant materials, dust, and water protection (IP ratings). |

| Human Safety Features | Lockout/tagout, arc flash protection, and warning systems. |

| Remote Monitoring | Real-time monitoring and alarm systems for proactive maintenance. |

Our electric furnace transformers are equipped with advanced safety features to ensure safe operation and long-term reliability in even the most demanding industrial environments. Whether for overload protection, short-circuit withstand, fire resistance, or human safety, our transformers are designed to meet stringent operational standards and offer peace of mind for operators and maintenance personnel. If you have specific safety requirements, we can further customize the design to meet your needs.

The expected lifespan of electric furnace transformers under normal operating conditions typically ranges between 20 to 40 years, depending on several factors such as the transformer’s design, operating environment, maintenance practices, and load conditions. Here’s a breakdown of the factors that can influence the lifespan of these transformers:

The expected lifespan of an electric furnace transformer is typically 20 to 40 years, with the exact duration depending on factors like:

With proper maintenance, transformers can reach the upper end of the lifespan range (30–40 years). Without maintenance or if exposed to harsh conditions (e.g., overloads, high humidity), the lifespan may be closer to 20 years.

By proactively monitoring and maintaining the transformer, you can ensure it operates efficiently and safely for many years, minimizing unplanned downtime and costly replacements.

The operational lifespan of our transformers is no less than 30 years.

While I don’t have access to specific proprietary customer data or case studies from external companies, I can certainly provide a general overview of the successful applications and industries where electric furnace transformers have been utilized, as well as typical outcomes. These examples are based on our industry practices, engineering knowledge, and successes that have been widely reported in the electrical transformer industry.

Case Study: Large Steel Manufacturing Plant (Global Steelmaker)

Key Features:

Case Study: Aluminum Smelting Facility (Asia-based Aluminum Producer)

Key Features:

Case Study: Industrial Foundry (North America)

Key Features:

Case Study: Copper Smelter (South America)

Key Features:

Case Study: Heat Treatment Facility (Europe)

Key Features:

Case Study: Precision Casting Facility (Middle East)

Key Features:

These case studies reflect the broad versatility and reliability of electric furnace transformers in various industrial applications, from steel and aluminum production to precision casting and copper smelting. Properly engineered transformers, with customized cooling systems, voltage regulation, and thermal management, have proven to be essential in ensuring safe, efficient, and long-lasting operation in challenging environments. If you are interested in more specific case studies or references, I recommend consulting engineering reports or industry publications that specialize in power systems and industrial transformer applications, or contacting suppliers directly for documented customer success stories.

The lead time for the delivery of electric furnace transformers can vary significantly depending on several factors such as the customization requirements, size and capacity of the transformer, manufacturing processes, and logistical considerations. Below is an overview of the typical lead times based on different scenarios:

For standard, non-customized electric furnace transformers that follow common specifications and industry standards, the lead time is typically shorter. The general timeline is:

Key Factors Influencing Lead Time:

For custom electric furnace transformers that need to be engineered to meet specific operational conditions or customer specifications (e.g., customized voltage levels, high harmonic filtering, special cooling systems, or integration with existing equipment), the lead time is typically longer.

Key Factors Influencing Lead Time:

For very large electric furnace transformers that handle extremely high voltages or power ratings, such as those used in large steel mills or smelting operations, the lead time may be extended further.

Key Factors Influencing Lead Time:

If a transformer is required urgently, some manufacturers may offer expedited production options. However, this often involves:

For example:

The typical lead time for electric furnace transformers is as follows:

For the best accuracy, it is important to discuss your specific requirements (such as customization, power rating, and voltage specifications) with the manufacturer or supplier. They will provide a tailored lead time based on the scope of the project and existing production schedules.

In response to fierce market competition and to meet customer demands, our company adheres to a market-oriented approach and a customer-centric philosophy. We have earned widespread recognition from our clients through efficient, comprehensive services and superior product quality.

We offer comprehensive after-sales services, including free guidance for installation and commissioning. After the product is operational, if the customer requires support, our service team will respond promptly:

Additionally, we have established a robust regular follow-up system. We conduct periodic written or on-site visits to monitor the performance of in-service products, ensuring our customers have continuous peace of mind.

Remote Technical Assistance

Our service team provides 24/7 online technical support, including video calls, troubleshooting guides, and documentation, ensuring immediate assistance regardless of time zones.

Detailed remote diagnostics can be conducted using customer-provided data or live visual inspections.

On-Site Support

For complex issues, we dispatch experienced technicians to the customer site promptly, adhering to the agreed international response timelines.

On-site services include installation guidance, commissioning, maintenance, and repairs.

Dedicated Service Representatives

Each international client is assigned a dedicated service representative to coordinate all aspects of after-sales support, including issue resolution and regular follow-ups.

Local Service Partnerships

We collaborate with certified local service partners in key markets to ensure faster response times and efficient support. These partners are fully trained in our products and processes to uphold our quality standards.

Regular Follow-Up Visits

Post-installation, we perform scheduled follow-up visits, either in person or virtually, to monitor product performance and address customer feedback. This proactive approach ensures optimal operation and customer satisfaction.

Why This Matters

Our comprehensive international service system combines swift response, advanced technical support, and localized expertise to provide our global clients with reliable and professional after-sales services. We are committed to building lasting partnerships through consistent support and excellence.

Yes, we offer on-site installation and commissioning services for electric furnace transformers as part of our comprehensive customer support package. These services are designed to ensure the transformer is installed, tested, and integrated seamlessly into your operations. Below are the details of our offerings:

Scope of Work:

Personnel: A team of certified engineers and technicians with extensive experience in transformer installation.

Tools & Equipment: We bring specialized tools and lifting equipment, ensuring safe and efficient installation.

Pre-Installation Checklist:

Testing & Verification:

System Integration:

Handover Documentation:

Training: Optional hands-on training for your technical team on operational best practices, safety, and routine maintenance.

Standard Package:

Premium Package:

Custom Packages:

Would you like a quote or further details for your specific project?

Contact us to get detailed information.

Spare parts and maintenance kits are not always included by default with the purchase of electric furnace transformers, but they can be offered as part of a customized package or purchased separately. Here’s a detailed breakdown of the options:

Basic Spare Parts:

For most transformers, the purchase typically includes a limited set of essential spare parts, such as:

Documentation:

We offer optional packages that can be tailored based on the transformer’s application and operating conditions. A typical spare parts package may include:

Maintenance kits are available to streamline periodic inspections and upkeep. These may include:

We ensure spare parts and maintenance kits are always available during the transformer’s lifecycle:

Would you like to explore a spare parts package or maintenance kit tailored to your specific transformer model and usage conditions?

Certainly! The packaging and shipping standards for electric furnace transformers are critical to ensure their safe delivery, integrity, and compliance with international shipping regulations. We follow strict protocols to ensure that your transformer arrives undamaged and is ready for installation. Below are the key packaging and shipping standards we adhere to:

Crating:

Electric furnace transformers are generally shipped in custom-designed wooden crates or metal enclosures to protect them from external damage during transit. These crates are typically constructed from high-quality timber or metal, with reinforced corners and shock-absorbing materials to minimize impact during handling and movement.

Internal Cushioning:

The transformers are securely strapped inside the crate using heavy-duty straps, and additional shock-absorbing foam or bubble wrap is used around delicate components like bushings, terminals, and cooling fans to prevent scratches or deformation.

Protection for Sensitive Components:

Road Transport:

For regional deliveries, the transformers are typically shipped via heavy-duty flatbed trucks equipped with cranes or hydraulic lifting systems for easy offloading.

Sea Freight:

Air Freight:

For expedited shipping, we can arrange air freight using cargo aircraft. This method is typically reserved for smaller transformers or urgent deliveries, though it is less common due to the size and weight of electric furnace transformers.

Crane Handling:

For heavy-duty transformers, a crane lift or forklift is used at loading and unloading points. The transformers are fitted with lifting eyes or steel straps for secure lifting, ensuring no damage to the equipment.

Compliance with Transport Regulations:

All packaging and shipping methods comply with international shipping standards, such as:

Insurance:

Insurance coverage for the transformer is typically provided, ensuring that the shipment is covered for any damage during transit.

Delivery to Site:

The transformer will be delivered to your designated installation site, where it will be unloaded using cranes or forklifts, depending on the site’s accessibility and the transformer’s weight and size.

Inspection:

Upon arrival, we recommend performing an inspection for any visible damage before signing off on delivery. Any damage should be immediately reported for claims processing.

Customer Support:

If needed, we can arrange installation and unpacking support by certified technicians to ensure the equipment is handled correctly during the unloading phase.

Tracking:

We provide real-time tracking of the shipment from dispatch to delivery. You can monitor progress via a dedicated online portal or tracking number.

Documentation Package:

You will receive a complete documentation package for the shipment, including:

If you have specific shipping requirements or need further details regarding the shipping of your electric furnace transformer, feel free to let us know. We can customize the shipping plan according to your preferences.

Upgrading or retrofitting existing electric furnace transformers is a common practice, especially when a facility wants to extend the operational life of its equipment, improve performance, or meet new operational requirements without replacing the entire transformer. There are several options available, depending on your goals, such as enhancing efficiency, increasing capacity, or modernizing the control systems. Below are the key options for upgrading or retrofitting electric furnace transformers:

Next Steps:

To move forward with a retrofit or upgrade, we recommend a thorough site evaluation and assessment of your transformer’s current condition, operational requirements, and future goals. Would you like to schedule a consultation or receive a custom quote for retrofitting your electric furnace transformer?

Post-sale support for electric furnace transformers is crucial to ensuring their long-term reliability, safety, and optimal performance. Here are some common and comprehensive post-sale support services that are typically offered by manufacturers and suppliers of electric furnace transformers:

By providing these post-sale services, we aim to not only extend the operational life of your electric furnace transformers but also reduce downtime, improve energy efficiency, and ensure safety compliance. Would you like to discuss any specific services in more detail or get a tailored support plan for your needs?

Maintaining electric furnace transformers is critical for ensuring their reliable operation, extending their lifespan, and minimizing downtime. A well-defined maintenance schedule is essential for keeping the equipment in optimal condition. Below is a recommended maintenance schedule based on typical industry practices, broken down into daily, monthly, quarterly, semi-annual, and annual tasks:

These are quick visual inspections that operators can perform at the start and end of each shift:

On a monthly basis, operators should perform the following tasks to ensure the continued safety and reliability of the transformer:

Every three months, a more thorough inspection and minor maintenance should be conducted:

At this interval, more detailed checks and testing should be performed:

This is the most thorough and comprehensive level of maintenance, often performed by a specialist or qualified technician. It includes all the previous tasks and additional deeper checks:

By adhering to this maintenance schedule, you can significantly enhance the operational lifespan, efficiency, and safety of electric furnace transformers.

The warranty service process for electric furnace transformers is a critical aspect of post-sale support, designed to ensure that the transformer functions correctly and reliably throughout its lifespan. Typically, the warranty service covers defects in materials, workmanship, and sometimes specific performance issues. Here’s a detailed overview of how the warranty service process is typically handled:

Before discussing the service process, it’s essential to understand the specific coverage that typically comes with the warranty:

For warranty service to be valid, registration of the transformer after purchase is often required:

When a fault or failure occurs within the warranty period, the process typically follows these steps:

If the failure is deemed to be under warranty, the following actions may be taken:

During the warranty service process, clear communication is essential:

Some manufacturers offer the option to extend the warranty beyond the standard period. This is typically offered as an extended warranty plan that can be purchased at the time of purchase or before the standard warranty expires.

The goal of the warranty service is to minimize downtime and ensure that the transformer continues to operate efficiently, offering peace of mind to the customer. Would you like more details on a specific aspect of the warranty service?

Yes, we provide comprehensive training for staff on the operation and maintenance of electric furnace transformers. Proper training is essential for ensuring that your team can operate the equipment safely, efficiently, and in line with best practices, ultimately prolonging the lifespan of the transformer and reducing the likelihood of unplanned downtime.

Operator training focuses on the day-to-day use and operation of the electric furnace transformer. It ensures that your staff can efficiently manage the equipment and quickly identify any potential issues.

Key areas of operator training include:

Maintenance training ensures that your maintenance team is well-equipped to carry out routine checks and resolve issues before they escalate. This helps to reduce unplanned downtime and avoid costly repairs.

Key areas of maintenance training include:

Routine Inspections: Teaching staff how to perform daily, monthly, quarterly, and annual checks to ensure that the transformer is functioning correctly and is properly maintained.

Oil Maintenance and Filtration: In the case of oil-immersed transformers, training on oil maintenance practices, such as oil sampling, oil quality testing, and oil filtration techniques to extend the transformer’s life and ensure it operates efficiently.

Testing and Diagnostics:

Handling Component Failures: Teaching how to detect, diagnose, and repair common transformer faults, including problems with:

Lubrication and Calibration: Instruction on proper lubrication of moving parts, such as the tap changer, and ensuring that all components are calibrated to operate within their designed parameters.

Preventive Maintenance Strategies: Training your team on how to implement preventive maintenance programs to avoid costly repairs, including how to schedule routine inspections and keep a log of maintenance activities.

End-of-Life Considerations: Educating maintenance staff on how to identify signs that the transformer is approaching the end of its operational life, and what steps need to be taken to either replace it or perform an overhaul.

For more advanced technical staff, we offer specialized troubleshooting and repair training to address more complex failures or issues that may arise. This includes:

Electric furnace transformers are high-voltage equipment, and ensuring the safety of your team is paramount. Our training includes:

We offer customized training sessions that cater to the specific needs of your plant, team, and transformer configuration. This can include:

Would you like to schedule a training session, or do you need additional information on specific training topics for your team?

When troubleshooting issues with electric furnace transformers, having access to the right resources is critical to identifying and resolving problems quickly and efficiently. Various tools, manuals, diagnostic procedures, and expert resources are available to help your team address common and complex issues. Below is a breakdown of the troubleshooting resources available for electric furnace transformers:

Operation and Maintenance Manuals: The primary resource for troubleshooting is the manufacturer’s official operation and maintenance manual. These manuals provide detailed instructions on:

Wiring Diagrams and Schematics: These diagrams are essential for tracing electrical faults and verifying proper wiring connections. If a component like a tap changer or protection relay is malfunctioning, the schematics can help pinpoint the issue.

Error Codes and Alarm Lists: Many modern transformers have built-in diagnostic systems that generate error codes or alarm signals. These codes are often listed in the manual and can help narrow down potential faults, whether they relate to overheating, load imbalances, or insulation issues.

Proper diagnostic equipment can help pinpoint faults more quickly and precisely. Here are some common tools used in transformer troubleshooting:

Insulation Resistance Tester (Megohmmeter): Used to check the insulation resistance of the transformer windings and bushings. If the resistance is lower than normal, it could indicate insulation breakdown due to moisture or contamination.

Dissolved Gas Analysis (DGA): For oil-filled transformers, DGA is a powerful tool for identifying internal faults. This analysis measures the gases dissolved in the transformer oil, which can indicate overheating, electrical arcing, or insulation degradation.

Thermographic (Infrared) Camera: Thermal imaging can detect hot spots on the transformer, which could indicate overheating or faulty components. For instance, hotspots on electrical connections or bushings may signify poor contact or insulation failure.

Transformer Turns Ratio (TTR) Tester: This tool checks the turns ratio of the transformer windings. A significant deviation from the rated turns ratio can indicate issues such as winding faults or transformer miswinding.

Vibration Analyzer: If there is unusual mechanical noise or vibration, a vibration analyzer can help identify issues with rotating parts like the cooling fans or tap changers.

Power Quality Analyzer: This device measures parameters like voltage, current, and harmonics, and can help identify issues related to load imbalances or voltage regulation.

Many modern electric furnace transformers come equipped with remote monitoring capabilities and built-in diagnostic tools that allow for continuous performance tracking:

Remote Monitoring Systems: Some transformers have sensors that continuously monitor key parameters (e.g., load, temperature, oil quality, and voltage). These systems often have web-based dashboards where real-time data can be accessed.

Predictive Maintenance Software: With IoT-enabled transformers, predictive maintenance software uses data analytics to detect early signs of potential failures based on trends and historical data, such as temperature spikes, load imbalances, or abnormal pressure readings.

Condition Monitoring Devices: These devices track parameters like oil temperature, moisture content, and gas levels in oil-filled transformers. Alerts can be sent to operators or maintenance personnel when readings exceed safe thresholds.

Troubleshooting guides or checklists offer a structured approach to diagnosing transformer issues. These often include step-by-step instructions for addressing specific faults:

Fault Detection Flowcharts: Flowcharts guide you through a decision-making process to narrow down potential causes based on the symptoms and alarms. For example, if the transformer is overheating, a flowchart may guide you through checking the load, cooling system, oil level, and ventilation.

Diagnostic Procedures for Specific Problems: These checklists focus on specific types of issues:

Step-by-Step Fault Isolation: These guides can be used to break down complex faults into manageable steps, isolating the problem to a specific component or system.

Sometimes, the issue may be beyond the capabilities of in-house personnel, and you may need the assistance of technical experts or service technicians. Resources available include:

Manufacturer’s Technical Support: Many manufacturers offer direct support through hotlines or email, where you can reach experts who can help guide you through the troubleshooting process or escalate the issue for further analysis.

On-Site Service Technicians: If the transformer is experiencing a more complex fault, manufacturers or third-party service providers can send trained technicians to perform advanced diagnostics and repairs on-site. Technicians are typically skilled in:

Training and Consultation: In some cases, manufacturers may offer additional training sessions or consultation services to help your team improve their troubleshooting and diagnostic skills.

In addition to technical documentation, the following resources are valuable:

Case Studies and Technical Papers: Manufacturers and industry organizations often publish case studies or white papers that document real-life troubleshooting scenarios. These documents provide insight into how similar issues were identified and resolved.

Technical Webinars and Workshops: Some manufacturers or service providers offer webinars or workshops that focus on troubleshooting common transformer issues, offering a chance to learn from experts in the field.

Under warranty or service agreements, manufacturers often provide troubleshooting assistance as part of the service contract:

Here are some common issues with electric furnace transformers and how to troubleshoot them:

Overheating:

Insulation Failure:

Oil Leaks:

Unusual Noise:

To effectively troubleshoot issues with electric furnace transformers, it’s crucial to have a combination of resources, including technical manuals, diagnostic tools, trained personnel, and manufacturer support. With the right resources and approach, many issues can be identified and resolved quickly, ensuring that the transformer operates efficiently and safely.

Would you like more detailed information on any of the specific troubleshooting tools or resources mentioned?

Yes, remote monitoring and diagnostics are increasingly available for electric furnace transformers, and many modern transformer models come equipped with advanced monitoring and diagnostic systems. These systems allow for continuous performance tracking, early fault detection, and data-driven maintenance, all of which contribute to enhancing the reliability, efficiency, and lifespan of the transformer.

Here’s a breakdown of how remote monitoring and diagnostics work for electric furnace transformers, as well as the key benefits and technologies involved:

Remote monitoring for electric furnace transformers involves installing sensors, communication devices, and data collection systems that provide real-time information about the transformer’s performance. The system continuously tracks key parameters, sends data to a centralized monitoring system, and alerts operators to potential issues.

With the data collected from the sensors, remote diagnostic tools analyze the information in real-time or over a historical period to detect potential issues or trends that may lead to a failure.

Several remote monitoring platforms and systems are available in the market, each tailored to the needs of electric furnace transformers. These platforms typically integrate with sensors and data acquisition systems to provide a comprehensive monitoring and diagnostic solution. Some of the common platforms include:

Many electric furnace transformers are integrated into a broader SCADA (Supervisory Control and Data Acquisition) system, which is used to manage the entire power distribution network. Remote monitoring data from transformers can be transmitted to SCADA systems, allowing for:

Yes, remote monitoring and diagnostics are not only available but are a critical component for modern electric furnace transformers. These technologies offer a wide range of benefits, from real-time performance monitoring and fault detection to predictive maintenance and enhanced operational efficiency. By using remote monitoring systems, transformer operators can ensure continuous, safe, and optimal performance, while also reducing downtime and maintenance costs.

Would you like more specific recommendations on remote monitoring systems for your transformers or details on how to implement them?

Yes, replacement parts for electric furnace transformers can typically be supplied quickly, depending on several factors such as the specific transformer model, supplier capabilities, and location. Here are key considerations that influence the speed of supply for replacement parts:

While most replacement parts for electric furnace transformers can be supplied fairly quickly, the speed depends on stock availability, part complexity, and your supplier’s logistics. If you have a specific transformer or component in mind, it’s advisable to confirm stock levels and potential lead times with your supplier in advance, especially for critical parts that may cause extended downtime if unavailable.

Upgrading or modernizing electric furnace transformers can significantly extend their lifecycle, improve efficiency, and reduce the risk of unexpected failures. Here are some recommended upgrades and modernization strategies to help achieve these goals:

Modernizing electric furnace transformers with the right upgrades—such as advanced cooling systems, improved insulation, real-time condition monitoring, digital controls, harmonic mitigation, and more—can significantly extend their service life. These upgrades not only improve the transformer’s longevity but also enhance overall system reliability, performance, and energy efficiency, leading to cost savings in the long term. Tailoring the upgrades to your specific operating conditions (e.g., load profile, environmental factors, and the age of the transformer) will ensure that your investment in modernization brings the best return.

In the event of a failure or emergency situation with electric furnace transformers, there are various emergency repair services available to minimize downtime and ensure that the system is back in operation as quickly as possible. These services often depend on the severity of the issue, the type of transformer, and the availability of parts and expertise. Below are some of the key emergency repair services available for electric furnace transformers:

Emergency repair services for electric furnace transformers are designed to address a wide range of failures and minimize operational downtime. These services include 24/7 support, on-site diagnostic and repair teams, quick parts delivery, mobile units for repairs, and specialized testing and replacement for critical components. Whether the issue involves winding damage, oil contamination, bushing failure, or cooling system malfunctions, these services help ensure that the transformer is quickly brought back to full functionality.

For industries with critical production needs, establishing a partnership with a reliable emergency service provider or having a maintenance contract in place is highly recommended to ensure fast and efficient responses during transformer failures.

Yes, there are specialized environmental disposal services available for outdated electric furnace transformers, ensuring that they are properly decommissioned and that hazardous materials are handled in accordance with environmental regulations. Due to the nature of electric furnace transformers, which can contain materials such as mineral oil (often used for cooling), insulating oils, PCBs (polychlorinated biphenyls), and metals like copper, aluminum, and steel, proper disposal is critical to minimizing environmental impact.

Here are the key services involved in the environmental disposal and recycling of outdated electric furnace transformers:

Disposal and recycling of electric furnace transformers are critical for minimizing environmental impact. Specialized environmental disposal services ensure the safe management of hazardous materials, including oils, PCBs, and metals, and work in compliance with all regulations. These services typically include:

Choosing a reputable, certified disposal service ensures that outdated transformers are disposed of responsibly, minimizing environmental harm and complying with legal requirements. If you’re dealing with outdated transformers, it’s essential to work with a service provider that specializes in transformer disposal, recycling, and hazardous waste management.

Taishan Transformer is a key national-level manufacturer specializing in transformers, recognized as a “Contract-Honoring and Promise-Keeping” enterprise, a high-tech enterprise, and a national-level enterprise technology center. It is recommended in the national directory for rural and urban power grid construction and renovation, as well as a recommended supplier of major electromechanical equipment for hydropower projects. Its products have been awarded the title of “National Quality Inspection Qualified Product – Quality Trustworthy Product” and “Nationally Recognized Product for Mechanical Industry Users.

Our products not only dominate the domestic market but are also exported to more than 30 countries and regions, including Russia, Southeast Asia, Africa, and the Americas, serving industries such as power, municipal engineering, metallurgy, and petrochemicals.

Have questions about our products or services? Interested in collaborating with us? Fill out the form, and a member of our team will get back to you promptly.

Tel / WhatsApp

info@taishantransformer.com

No. 367 of Tianzhufeng Road, Taian, Shandong, China,271000

Shandong Luneng Taishan Power Equipment Co., Ltd., a subsidiary of Taishan Group, has 60 years of expertise in power equipment production, manufacturing, and R&D. It oversees five subsidiaries: Taian Taishan Electric Co., Ltd., Taian Taishan High Voltage Switch Co., Ltd., Shandong Taishan Electrical Equipment Co., Ltd., Taian Huaneng Insulation Material Co., Ltd., and Shandong Luneng Cable Co., Ltd.

We're here for you !

let's Talk about your Project!